In today's world of emphasis on material quality, having reliable testing equipment is crucial. Using Bursting Strength Tester can help quality control personnel such as manufacturers and designers evaluate material strength. Let’s discuss how to improve product quality through Fabric Bursting Strength Tester.

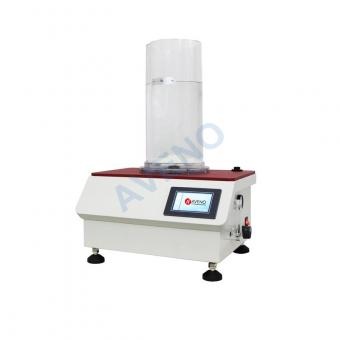

Bursting Strength Tester AG10

Bursting Testing Machine for fabric is an instrument specially used to measure the burst resistance of materials. It is used to measure the expansion force and divergence rate of fabrics, woven fabrics, knitted fabrics, non-woven fabrics, paper and cardboard. By subjecting materials to increasing amounts of pressure, burst strength testers can determine their breaking point, providing valuable insights into their tensile strength and overall durability.

Application fields: This machine is mainly used in the textile industry and packaging industry.

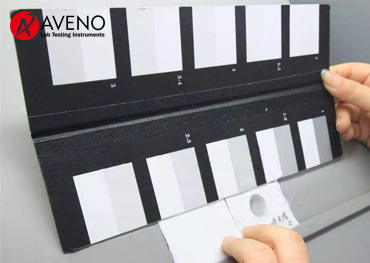

1. Textile industry: Corresponding quality researchers of textile manufacturers will use Bursting Strength Test Equipment to evaluate the strength and durability of fabrics to evaluate the quality situation.

2. Packaging industry: Fabric Bursting Strength Tester play an important role in evaluating the strength of packaging materials such as cardboard, paper, and laminates. By testing the maximum burst pressure of the materials, manufacturers can ensure that the packaging can withstand various handling and transportation conditions. This serves to protect the internal products.

AG10B Bursting Strength Tester

AN15 Carton Bursting Strength Tester

User ease of use:

The design of the Fabric Bursting Test Instrument takes user convenience into full consideration, which not only makes the operation more convenient for technicians, but also allows novices to get started more quickly.

1. Color touch screen control, the interface is simple and easy to understand, the operation is simple and intuitive, and the touch is sensitive.

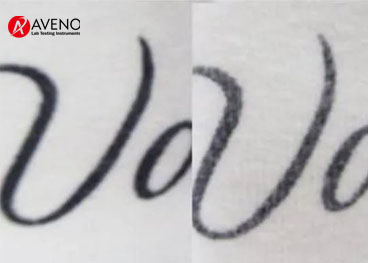

2. The test cover is made of highly transparent organic glass with built-in LED lighting, so that the sample experiment process can be clearly observed; it is installed with magnets, making it easy to replace and disassemble.

3. The automatic induction blasting system is sensitive and reliable. The instrument has over-range and over-expansion protection functions.

4. A plexiglass cover is installed on the outside to prevent people from being pinched, making it safer to use.

5. Using high-speed AD sampling and 32-bit ARM processor, high sampling frequency and high test accuracy.

6. Fast and accurate results: Automated testing processes ensure fast results and eliminate manual errors. Precise measurements help accurately determine a material's bursting strength.

Bursting Strength Tester provide friendly assistance to many manufacturers when screening materials and are good partners for enterprises in quality control. By investing in burst strength testers, companies can enhance their manufacturing processes, reduce costly product failures, and maintain market share. Competitive Advantage.

Anything inquiry please contact us as below:

AVENO technology co., ltd.

Email: sales@avenotester.com

+8615280858852

+8615280858852

Nov 18, 2024

Nov 18, 2024

online service

online service +8615280858852

+8615280858852

+8615280858852

+8615280858852